Electrocoat

Layer Without Limits

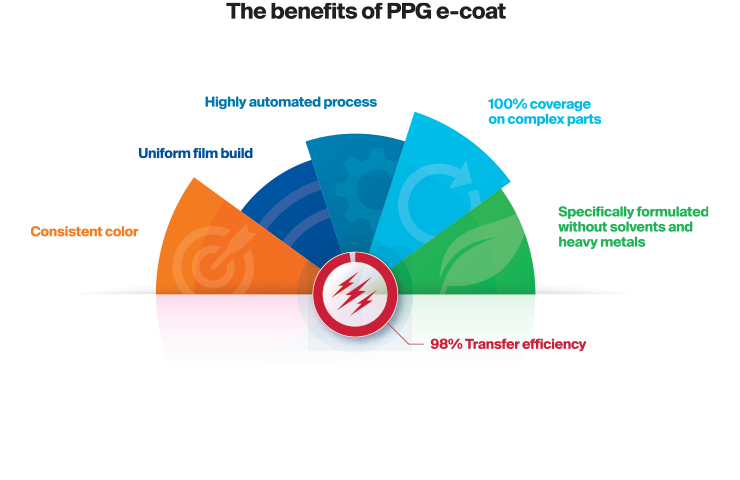

Deliver next-level efficiency with 98% color consistency and uniform film build.

As the company that pioneered electrocoat in 1963, PPG continues to set the global standard for e-coat performance, innovation and technical service.

PPGs comprehensive mix of anodic and cathodic products delivers a corrosion-resistant and chemical-resistant finish that meets both standard and high-edge requirements. Our e-coat products have low applications costs and are specifically formulated without solvents and heavy metals.

More efficient than other dip applications, e-coat is highly automated and delivers 98 percent transfer efficiency, color consistency and uniform film build on even the most complex metal parts.

It is the coatings system of choice for makers of military and HVAC equipment, automotive parts, appliances and fasteners.

Segments

-

Automotive Parts and Accessories

A global innovation leader in the automotive parts and accessories industry, PPG provides coatings, sealants and adhesives for a broad array of substrates and external, internal and underbody parts to every major domestic and foreign automaker in the world.

-

Heavy Duty Equipment

With an in-depth knowledge of the industry, market-proven protective coatings and extensive color capabilities, PPG is trusted by leading regional and global heavy-duty equipment OEMs to protect their products and their brands.

-

Appliance

For more than 50 years, PPG has provided major commercial and household appliance manufacturers with protective coatings that add durability, color and style to their residential and commercial equipment.

-

General Industrial

For more than a century, leading manufacturers have relied on PPG for protective, cost-effective and colorful general industrial coatings to make their products more durable and their processes more efficient.

Featured Products

For detailed product information and specification click here >>

-

PPG POWERCRON® 10X™

POWERCRON® 10X™ is a resin modified to provide balance in appearance/edge coverage while maintaining low temperature cure.

-

PPG POWERCRON® ADVANTEDGE™ Electrocoat

Powercron Advantedge is a ninth-generation tin-NIA (not intentionally added) electrocoat specifically engineered to provide high-edge protection of cut, stamped or formed edges on complex metal parts. Cure temperatures as low as 320°F (160°C) can help manufacturers reduce energy costs and related carbon emissions.

-

PPG POWERCRON 6000CX

PPG Powercron cationic epoxy technology is known for its ability to work across a broad variety of shapes and sizes, as well as its single- or two-component feed-package options. Offering good edge protection for standard-edge parts and standard coverage of densely racked parts.

-

PPG POWERCRON® 6100HE

PPG Powercron 6100HE electrocoat uses high-performance cationic epoxy technology; a two-component package with metal-based catalyst. Providing excellent throwpower and uniform high-edge coverage of complex parts with the added benefit of an improved surface profile.

-

PPG FRAMECOAT® II: Electrodeposition Coating

Framecoat II is PPG's high-performance cationic epoxy electrocoat technology that provides excellent edge coverage with the added benefit of an improved surface profile. Formulated without lead, it is a state-of-the-art electrodeposition primer formulated to deliver improved corrosion resistance for automotive parts and light-truck chassis components.