Curing is an important process to maximise the performance of fluoropolymer coatings by achieving adhesion, chemical resistance and necessary surface properties.

Although PPG coatings are manufactured to be easy to apply, achieving these characteristics can only be accomplished if the cure is done correctly and according to the product data sheet (PDS) provided.

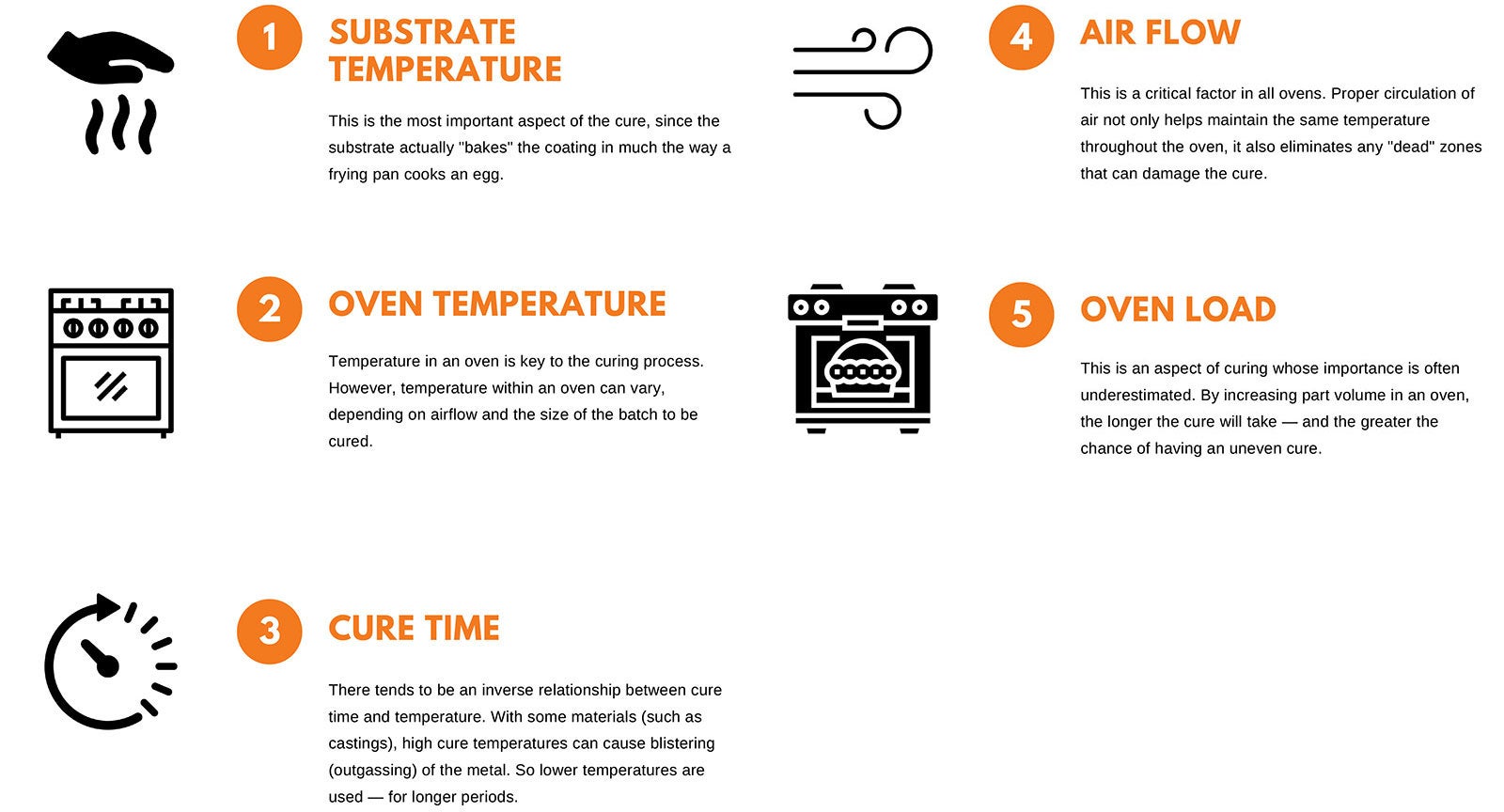

The below five elements should be carefully monitored to help achieve a proper cure:

1. Substrate Temperature

This is the most important aspect of the cure, since the substrate heats up causing the coating to set (i.e. cure). It is important to remember the time required to reach the peak metal temperature will vary depending on the substrate type and its weight. An extended high-temperature cure may be necessary to melt the fluoropolymer components into a coating system.

2. Oven Temperature

The temperature of the oven during curing is also key. It is important to know that an oven’s temperature can often vary depending on airflow and the size of the batch to be cured. The most common methods are either conventional thermal or convection but there are also special types like infra-red that will heat the metal substrate directly.

3. Cure Time

There tends to be an inverse relationship between cure time and temperature. Some materials, such as castings, can cause blister when subjected to high cure temperatures and therefore require lower temperatures for longer periods of time. However, lowering the cure temperature can occasionally change the characteristics of the dry coating film, no matter how long a coating is cured. An extended cure can degrade coatings by reducing gloss or not achieving the ideal colour.

4. Air Flow

Proper circulation of air not only helps maintain the same temperature throughout the oven, it also eliminates any ‘dead’ zones or areas of inconsistent temperature, which can prevent a proper cure. The air flow must also be controlled in order for fumes to be emitted through exhaust systems and not escape into the workplace where they could cause a health hazard or, in some cases, unpleasant odors.

5. Oven Load

Oven load is an aspect that should not be underestimated. As the volume in an oven increases, the cure will take longer and the chance of having an uneven cure increases due to a reduction in temperature. A heavy load in a line oven may require slowing the production line speed, just as a full batch oven may require additional time.

Achieving the ideal cure is not always easy due to the many variables; however, with the right tools and support from your coating supplier, it can be achieved.

For further advice for achieving the best cure for your PPG coating, contact us.